LOTTE Chemical Begins ‘Constructing a Virtuous Plastic Recycling System’

Originally invented as a substitute for ivory when making billiard balls, plastic has become a material that were encounter daily. In fact, plastic is so entrenched in our daily lives that it is hard to imagine a plastic-free world.

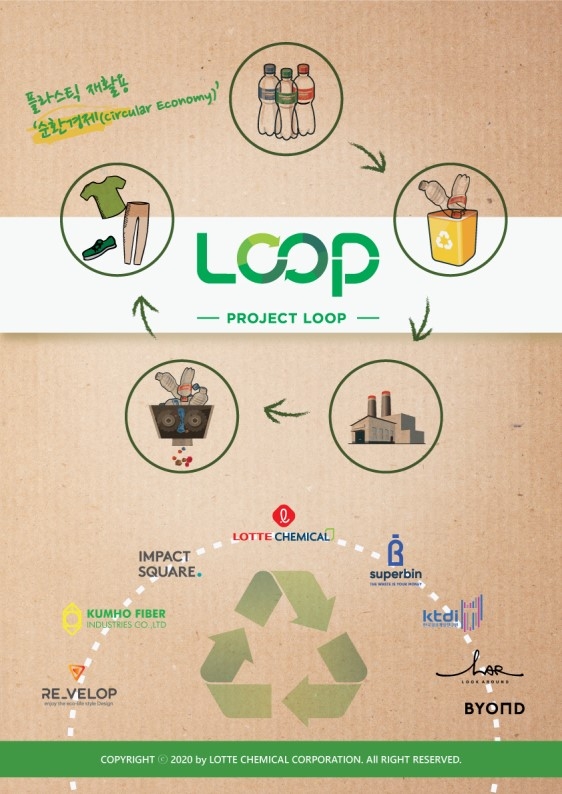

Despite its cost efficiency and convenience, however, plastic is one of the most harmful products to our environment when improperly discarded. As part of the solution for this dilemma, LOTTE Chemical initiated ‘Project LOOP’ with seven related corporations and organizations to construct a virtuous plastic recycling system. Asia Society Korea interviewed Mr. Gyo-Hyeon Kim, the CEO of LOTTE Chemical, to learn more about this project.

1. How did you come up with this project?

During my numerous years in this industry, it has always pained me to see plastic continuously criticized. As I always say, it is the throwing away of plastic that causes the problem, not plastic itself. We cannot deny that a world without plastic, a ‘plastic-free world’, is impossible. Thus, it is only logical to approach the plastic waste problem as a ‘how to properly use and discard plastic’ issue rather than a ‘how not to use plastic’ issue.

According to the United Nations Environment Program (UNEP), humanity has created 8.3 billion metric tons of plastics, of which only nine percent was recycled. Naturally, the issue of plastic waste should focus on how to recycle the remaining 91 percent. This project aims to create a ‘Virtuous Plastic Recycling System’ that increases the plastic recycling rate and constructs a self-sustaining plastic environment.

2. Can you briefly explain the recycling process?

‘Project LOOP’ is an initiative where eight different corporations and organizations have gathered together with one objective: “to construct a Virtuous Plastic Recycling System”.

LOTTE Chemical and IMPACT SQUARE have taken charge of the overall design and coordination of this project, and SuperBin has taken the responsibility of collecting discarded PET bottles with its automatic plastic collecting AI robot, Nephron. Kumhofiber will transform the used plastic into flakes – a form of raw plastic material – that will then be reprocessed into fiber materials by the Korea Textile Development Institute (KTDI). Finally, LAR, Project BYond, and Re-Velop will produce final goods, such as shoes, bags, and other fashion goods.

As you can see, the entire recycling process is an intricate process that requires various counterparts and their expertise. This project was only possible thanks to the participation of various groups that felt responsible for the numerous environmental issues that humanity is facing. We are grateful to the corporations and organizations that joined our mission, and we will continue to search for ways to contribute to a better society through our strengths and abilities.

3. What are your expectations for this project in both the short term and the long term?

As for the short-term prospects, I hope that this project directs the public’s attention to the ongoing environmental crisis that we face today. This project was possible thanks to the help of other eco-friendly groups, but it will only accomplish half its mission without the participation of citizens. I sincerely hope that the public will complete the other half of the mission by actively participating in the construction of a virtuous plastic recycling system.

For the long-term prospects, I hope that our mission will be the start of many more projects to come. While it may be difficult and impractical for us to decrease the use of plastic at a significant level, we can always think of innovative ideas that will save our environment while maintaining the same standard of living that we enjoy today.

The plastic issue that we now face calls for collective global action in which both corporations and citizens must actively participate. Each baby step that we take will gradually merge into one giant step toward a sustainable future.